MS-1261A/DWS

High-speed, feed-off-the-arm, 3-needle double chainstitch sewing system (Digital workstation)

MS-1261A/DWS

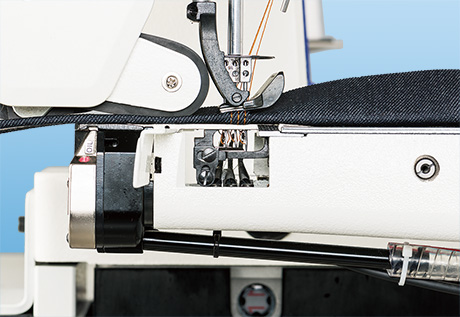

The multi-layered part detection sensor helps feed the material smoothly allowing the sewing machine to produce beautiful seams

The MS-1261A is provided with digital functions for preventing stitch skipping and stitch gathering as well as for supporting smooth feed of multi-layered parts of materials that are considerably heavier in weight than the other parts of materials. These capabilities are highly required in sewing jeans.

The newly-developed machine head is provided as standard with the presser foot pressure control function that has the multi-layered part detection sensor. In combination with the belt-type digital cloth puller which enables the digital setting of the belt presser foot pressure and feed length, the sewing machine achieves "more beautifully finished seams".

Support to the digital control facilitates the adjustment of sewing for various kinds of materials. Even when sewing heavy-weight materials, the sewing system produces soft and beautiful seams.

Prevention of stitch skipping

Through the improvement to the feed locus, needle bending is prevented by decreasing the feed amount when the needle penetrates the material. As a result, the looper thread is securely retained to ensure stable loop formation, thereby allowing the looper to catch the needle thread appropriately to produce seams without fail. In addition, the backward-moving type needle guard helps feed heavy-weight materials smoothly, thereby preventing the occurrence of stitch skipping.

The sewing system offers improved operability for the operator and promotes energy savings

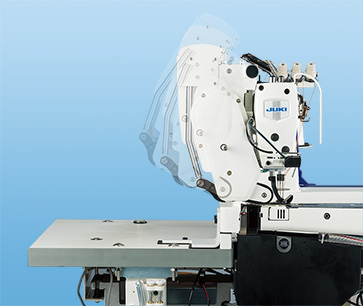

The conventional feed-off-the-arm chainstitch machines have specially-shaped machine heads due to their stitch type.

In pursuit of ease of sewing and ease of handling of materials, the MS-1261A/DWS has adopted a newly-developed machine head the shape of which is like of the general-purpose sewing machines.

The MS-1261A/DWS is the first sewing system that comes with an energy-saving high-powered direct-drive motor. As a result, workability and maintainability are improved.

Management of sewing performance and sewing machine by the utilization of IoT (Internet of Things)

Management, browsing, and editing of data can be carried out on the application software

Data on sewing machine adjustments made according to the product to be sewn can be transferred to a commercially available Android tablet in contactless mode. This enables quick check for uniform settings as well as confirmation of conditions of sewing machines in a sewing line, thereby facilitating setup changes.

The operation panel is also provided as standard with a USB port.

Data management and software updates can be carried out with ease using a USB thumb drive.

Data items of sewing can be numerically managed to ensure "stable quality" and "reduction in time required for setup changes". Quantified sewing data can be externally taken from the sewing machine using an Android tablet or USB thumb drive.

JUKI Smart APP allows you to send and confirm various data

In the application, there are items of management setting (terminal registration), sewing machine data (sewing data), problem-solution chart.

In the problem-solution chart, we can generate production graphs, the availability chart, etc. for each acquired sewing machine data so it can be used for checking the current situation and analyzing it.

Belt-type digital cloth puller

This belt-type digital cloth puller prevents stitch skipping and stitch gathering that are likely to occur at multi-layered parts of material.

The "belt presser foot pressure" and "feed length" can be set on the operation panel of the sewing machine. This digital cloth puller is provided with both the roller surface that is soft to the materials and strong feeding force.

The digital cloth puller can be lifted up only by operating the lever.

This promises easier maintenance.

Chain-off thread cutter

This chain-off thread cutter is provided with a sensor. As a result, the cutter can be operated only when it is necessary.

The operation of the cutter and that of the vacuum can be separately set to ON and OFF on the operation panel.

The cutter only operates at the beginning and end of sewing, thereby contributing to improved durability.

Needle cooler

The needle becomes hot during high-speed sewing.

The needle cooler blows air to the needle during high-speed sewing to prevent the needle from becoming so hot as to cut the thread by its heat.

LED hand light

Light quantity of the LED hand light can be adjusted in five levels.

The LED hand light can also be turned OFF. With the LED hand light, the brightness can be adjusted to allow the operator to carry out sewing work with ease, thereby improving work efficiency.

*Auto-lifter is also included in the standard equipment.

| Model | MS-1261A /DWS | MS-1261AM / DWS |

|---|---|---|

| Application | Heavy - to extra heavy - weight | Medium - to heavy - weight |

| Max. sewing speed | 5‚500sti/min* | |

| No. of needle | 3 | |

| Feed | Bottom feed | |

| Needle bar stroke | 33.2mm | |

| Needle gauge | 6.4mm(1/4”) | |

| Stitch length | 1.4mm - 4.2mm | |

| Lift of the presser foot | 10mm | |

| Needle | UY128GAS #16~#22 (Standard #21) | UY128GAS #16~#21 (Standard #19) |

| Thread take-up lever | Needle bar thread take-up lever | |

| Circumference of tube at the needle entry | 194mm | |

| Needle guard | Backward travelling needle guard | |

| Lubricating oil | JUKI New Defrix Oil No.1 (equivalent to ISO VG7) | |

| Lubrication | Automatic lubrication | |