MO-6900C

Super High Speed, Cylinder Bed, Overlock Machine

MO-9000C

The machine provided with a small-in-diameter cylinder bed, is capable of run stitching or blind-hemming tubular materials, such as sleeve cuffs, with ease. The MO-6900C Series sewing machine, provided with a small-in-diameter cylinder bed, is capable of runstitching or blind-hemming tubular materials, such as sleeve cuffs, with ease. The operator can carry out sewing of the tubular material while turning it downward. This promises improved workability and contribute to dramatically increased productivity.

The machine ensures both beautiful and upgraded seam quality at higher speeds.

Since the machine comes with a needle-thread take-up mechanism as well as a looper thread take-up mechanism, to enable sewing with a lower tension applied to the material, it achieves soft-feeling high-quality seams.

Mechanisms that promise improved operability.

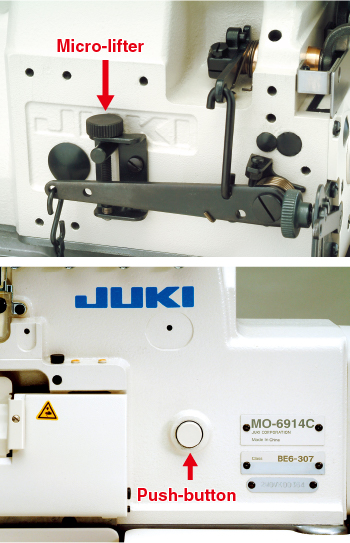

Since the machine is provided as standard with the bottom feed dog inclination-adjusting mechanism and the external differential feed-increasing mechanism, it can be easily adjusted to ideally match the material being sewn. In addition, the machine is provided as standard with a micro lifter feature that offers improved responsiveness to materials and provides the operator with upgraded operability. The stitch length can be easily adjusted with the push-button mounted on the front surface of the sewing machine.

Further increased reliability.

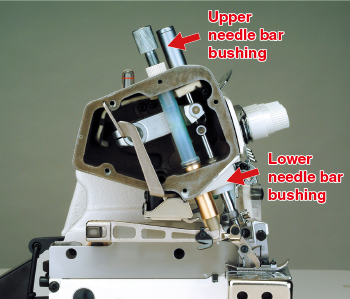

The introduction of a shield-structured needle bar mechanism and upper and lower needle bar bushings contributes to increased durability and reliability. The machine is provided as standard with a cartridge-type oil filter and cooling fan, thereby ensuring enhanced reliability.

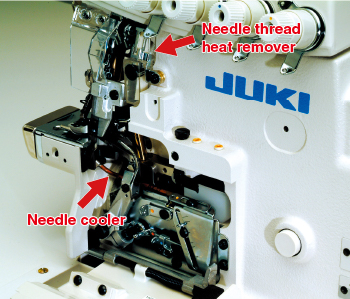

The needle thread heat remover and needle cooler are equipped as standard.

To offer improved sewing capabilities as well as to prevent stitching mishaps during high-speed sewing, the machine is provided as standard with the needle thread heat remover and needle cooler.

Small-in-diameter cylinder bed.

The cylinder bed is best suited to the runstitching and blind hemming of tubular materials. Gauges and devices you have used with your existing JUKI machines are also interchangeable with no additional machining required. This eliminates both the waste of resources and unwanted extra costs.