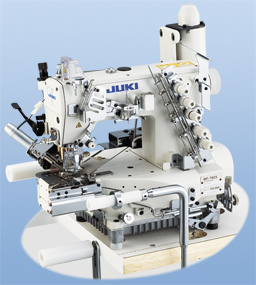

MF-7900-E22, MF-7900-E23

High-Speed, Cylinder-Bed, Top and Bottom Coverstitch Machine (Endless Spandex Elastic Band Attaching)

MF-7900-E22 (With Manual Binder)

MF-7900-E22/UT (With Manual Binder) (Automatic Thread Trimmer)

MF-7900-E23 (With Air Binder)

MF-7900-E23/UT (With Air Binder) (Automatic Thread Trimmer)

The machine is used for spandex elastic band sewing processes for briefs. The machine produces soft seams, making it best-suited for band attaching processes where seams are required to have sufficient elasticity.

E22 For endless spandex elastic band attaching

(with manual binder and tension roller)

E23 For endless spandex elastic band attaching

(with air binder and tension roller)

This model is best suited for sewing elastic bands on briefs. E22 is opened / closed with the knee lever and E23 is opened / closed with the knee switch. The machine comes provided as standard with a tension roller to smoothly sew elastic bands on different-sized garment bodies. The machine flexibly adapts to varying elasticities due to its soft seams.

JUKI's dry-head technology protects sewing products from being stained with oil

With the excellent functions inherited from the MF-7900 Series, the MF-7900D is provided with a dry frame mechanism to eliminate the cause of oil stains. Stain removing work or re-sewing work is substantially reduced by protecting sewing products from being stained with oil, thereby improving the quality of finished products.

Thanks to the new feed mechanism, many different types of sewing are achieved

The feed locus can be adjusted externally. The feed locus is now adjustable in terms of the vertical direction and horizontal direction, thereby improving responsiveness to sewing materials.

Differential-feed micro-adjustment mechanism

It is possible to finely adjust the differential feed amount to a best-suited value for the material to be used. The differential feed ratio is constant even if the stitch length is changed.

The looper thread twining prevention mechanism has been improved and is provided as standard for the sewing machine

In the case of looper thread breakage, the looper thread twining prevention mechanism is activated to trim the looper thread before the thread twines on the looper thread cam. In this way, the looper thread twining prevention mechanism prevents the looper thread from twining on the looper thread cam. In addition, the looper thread cam, which has been incorporated in the sewing machine, has been changed so that it is mounted outside of the sewing machine. The externally-mounted looper thread cam promises improved maintainability.

Micro-lifter mechanism

Elastic material or delicate material can be sewn with the presser foot kept slightly raised. This effectively helps reduce the degree of slippage, warpage, and damage of the material.

| Model | MF-7900-E22‚23/PL |

|---|---|

| Lubrication | Automatic (frame: no lubrication) |

| Max. sewing speed | 5‚000sti/min |

| Max. stitch length | 0.9~3.6mm |

| Needle gauge | 5.6‚6.4mm |

| Needle | UY128GAS( #10S) #9S~#12S |