LU-2810A-70BBS/X73178

Semi-dry Direct-drive, 1-needle, Unison-feed, Lockstitch Machine

with automatic thread trimmer (Vertical-axis 2.7 Fold-Capacity Hook type)

Double tension provided as standard

A dual-tension is provided as standard responding to the sewing with thick thread under a higher tension.

Multi-functional G-string switch with automatic thread trimmer)

The machine with thread trimmer can change over the needle thread tension from single to double and vice versa (increase the responsiveness to thicker materials), change over the alternating vertical movement amount, the stitch length, etc. by simply pushing the Multi-functional 6-string switch.

New bobbin thread spool device

New bobbin thread spool device is no necessity of rolling thread manually.

Higher lift of the presser bar

A 20mm presser bar lift is achieved by automatic presser bar lift, which provides easy operation for joining leather and thick sponges often applied to making luxurious sofas.

Walking-foot/presser-foot alternating vertical movement mechanism

The adopted feed mechanism makes up less variance of the balance of the alternating vertical movement amounts. The maximum presser foot lift is 9mm which can be adjusted with ease by the large dial on top of the machine head.

2. 7 told-capacity hook

With the adoption of this vertical-axis 2.7 fold-capacity hook, the frequency of bobbin thread winding is reduced, promising sewing work of increased efficiency. The hook which can be adjusted with screw amount of needle guard contact to needle.

Eccentricity of the feed driving cam is adjustable.

Adjustment of the eccentricity of the feed driving cam has been enabled. As a result, the sewing machine is able to perform sewing with the feed that is best-suited to the material and thread used. It is no longer necessary to prepare other subclass model sewing machines.

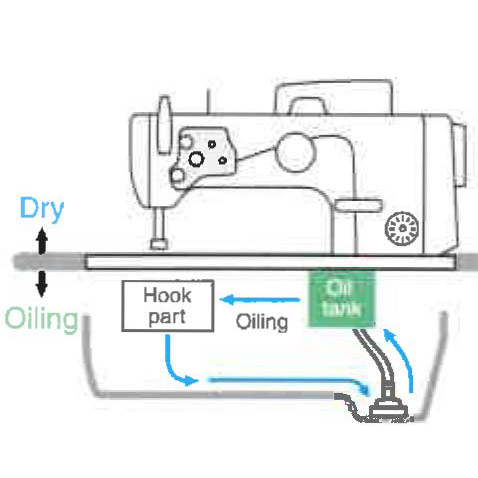

New-type tank style automatic lubrication mechanism has been adopted.

The oil dropped from the hook and its surrounding sections into the under-cover is filtered to remove dirt and dust and is then returned to the oil tank. This method saves the effort of oiling and reduces oil consumption. The remaining oil quantity indicator is provided on the front face of the machine head. Lubrication can be carried out without tilting the machine head.

| Model name | LU-2810A-7 /X73178 |

|---|---|

| Application | 1-needle with automatic thread trimmer |

| Max. sewing speed | 3‚000sti/min |

| Max. stitch length | 9mm |

| Stitch length dial | 1 pitch dial |

| Presser foot | Auto: 20mm‚ By hand: 10mm |

| Auto lifter | Provide as standard |

| Alternating vertical movement | 1-9mm |

| Alternating vertical movement adjusting method | Large dial |

| DL device | Provide as standard |

| Needle thread tension | Single/Double-tension |

| DL device | Provided as standard |

| Needle thread tension | Single/Double-tension |

| Hook | Vertical axis 2.7 fold-capacity hook |

| Bottom-feed micro-adjustment mechanism | Provided as standard |

| Needle | 135x17 Nm160 (Nm125-Nm180) |

| Thread | #30-#5‚ B46-B138‚ Nm=60/3-20/3 |

| Lubrication | Semi-dry head automatic (Tank system) |

| One-touch type reverse feed switch | Provide as standard |

| Hand switch | Multi-functional 6-string switch |

| Safety mechanism | Provid as standard (reset with the push of a button) |

| Power requirement/ Power consumption | Single-phase 100-120V / 200-240V‚ 3-phase 200-240V / 1 B0VA (with automatic thread trimmer) |

| Machine head weight | 61kg |