LU-2800V-7 Series

LU-2800V-7 Series

Management of sewing performance and sewing machine by the utilization of IoT (Internet of Things)

Management, browsing, and editing of data can be carried out on the application software

Data on sewing machine adjustments made according to the product to be sewn can be transferred to a commercially available Android tablet in contactless mode. This enables quick check for uniform settings as well as confirmation of conditions of sewing machines in a sewing line, thereby facilitating setup changes. The operation panel is also provided as standard with a USB port. Data management and software updates can be carried out with ease using a USB thumb drive. Data items of sewing can be numerically managed to ensure “stable quality” and reduction in time required for setup changes. Quantified sewing data can be externally taken from the sewing machine using an Android tablet or USB thumb drive.

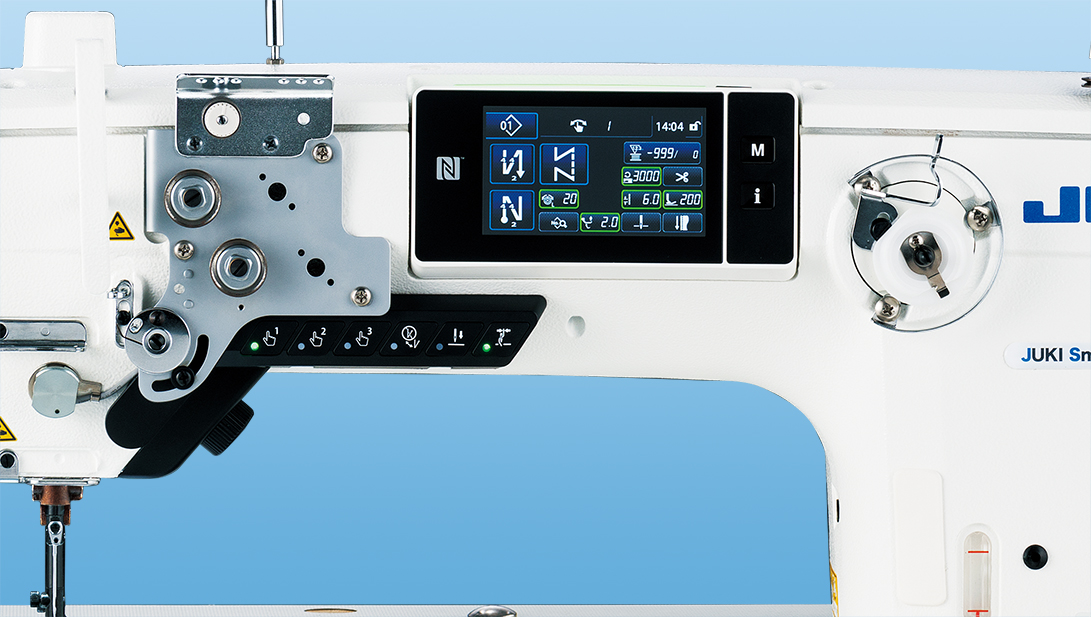

Adjustment of sewing condition is displayed on one screen

Sewing conditions can be set easily since sewing conditions such as thread tension, stitch length, presser foot pressure, alternate vertical movement amount, etc. are displayed on one screen.

Energy-saving effect

Automatic OFF function of the operation-panel backlight The operation-panel light can be turned OFF after a lapse of the preset time. Sleep mode (Automatic power-OFF function) If no operation is carried out for a predetermined period of time, the power supplies to the motor, etc. can be automatically turned OFF. *These options can be set up on the operation panel.

Active presser foot pressure mechanism

The presser foot pressure is digitally controlled

Digital control system controls the presser foot pressure. Under the automatic mode, the multi-layered section detection function detects changes in material thickness to increase/decrease the presser foot pressure accordingly. Under the manual mode, the presser foot pressure control function is assigned to the hand switch to enable operation with the hand switch.

Best-suited stitches are produced at multi-layered parts of material

Multi-layered part detection function

Multi-layered parts of the material which occur in the case two or more plies of material are sewn or different kinds of material are sewn can be detected by the multi-layered part detection function to change over the stitch length, thread tension, presser foot presser and amount of alternate vertical movement to those that have been predetermined for sewing those parts of the material.

Setting of thresholds for the multi-layered part detection

Under the teaching mode for the multi-layered part changeover ON sensor value, the material thickness at the normal part and that at the multi-layered part of the material can be measured with ease. The automatically-measured thresholds can be set as those for the multi-layered part detection.

Improvement of operability by means of the jog dial

The operator is able to turn the main shaft (for moving the needle bar up and down) only with the jog dial without stretching his/her arm to the hand wheel. When the jog dial is pushed, it can be used as 1/2 needle-stitch correction switch (one-touch function).

Multi-functional 6-string switch

The sewing data (stitch length, needle thread tension, amount of alternate vertical movement, presser foot pressure and sewing speed) can be changed easily with the one-touch changeover switch to obtain the ones that have been elaborated according to sewing conditions. The sewing data (stitch length, needle thread tension, amount of alternate vertical movement, presser foot pressure and sewing speed) can be changed easily with the one-touch changeover switch to obtain the ones that have been elaborated according to sewing conditions. Four different one-touch functions can be assigned to six-gang hand switches [1] to [6], touch-back switch and jog dial, at the maximum.

Other continuous sewing conditions

For settings corresponding to continuous sewing conditions (polygonal shape stitching function), more beautifully finished seams are produced by using various functions (custom-pitch setting function, reverse-feed stitching function).

Example: Sewing conditions in the case of using the polygonal-shape stitching function (LU-2828V-7)

In the case of sewing materials 1 and 2 that differ in thickness to the base material (material thickness), the sewing conditions can be easily changed over to the best-suited ones on a step-by-step basis. (The number of stitches, one-touch changeover, and multi-layered part detection are used as the step-by-step changeover triggers.)

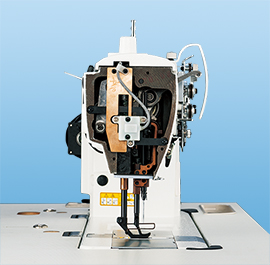

Bobbin thread spool device

Bobbin thread spool device is no necessity of rolling thread manually.

Maintenance work carried out safely (Standby switch)

When the standby switch is pressed, the sewing machine does not start unexpectedly even if the pedal is depressed. When the standby switch is pressed, operations through the operation panel, and with the machine 6-string switch and jog dial are also disabled, thereby allowing sewing-machine maintenance work such as threading, needle replacement, gauge replacement to be carried out safely. (In this case, the pulley can be turned by hand.)

High-torque direct-drive motor is installed

The direct-drive motor system has been adopted by all of the sewing systems with a thread trimmer. As a result, the sewing machine starts up swiftly and promises increased stop accuracy, thereby demonstrating improved responsiveness.

LED Light

The LED light can adjust the light intensity to 5 levels, and an Off setting is also possible. The operator can set the brightness which is easy to work with, improving work efficiency.

LU-2828V-7

Semi-dry Direct-drive, 1-needle, Unison-feed, Lockstitch Sewing System with automatic thread trimmer

(Vertical axis 2.7 fold-capacity hook / Shorter - thread remaining type)

Shorter - thread remaining type

The shorter-thread remaining type LU-2828V-7 is a high-performance sewing machine. It leaves a shorter thread on the material at the beginning of sewing by means of the needle thread clamp device, as well as at the end of sewing by means of the thread trimmer which is provided with a shorter thread remaining function. This means that manual thread nipping both at the beginning and at the end of sewing is no longer required, thereby helping reduce operator fatigue. Thanks to the adoption of a 2.7-fold hook, the frequency of bobbin thread changing are reduced and workability is improved.

Beautiful finished seams

Needle thread clamping device

This device pulls the needle thread into the wrong side of the material at the beginning of sewing, thereby ensuring more beautifully-finished seams.

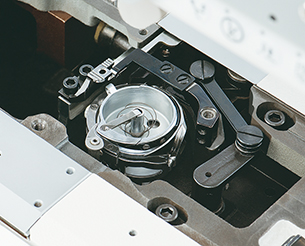

The shorter-thread trimming mechanism (needle thread roll-in and shorter-thread remaining type)

The thread trimming mechanism has been completely renewed. The industry's shortest remaining thread length achieved by trimming the thread close to the fixed knife at the last stitch (condensed stitch). (The length of the remaining needle thread is 5mm)

Needle tension is digitally controlled

Needle thread tension that matches sewing conditions given can be set on the operation panel and stored in memory. The needle thread tension adjustment needs experience. However, for this sewing machine, thread tension data stored in memory is reproducible, thereby reducing the setup time when the product to be sewn is changed.

LU-2860V-7

Semi-dry Direct-drive, 2-needle, Unison-feed, Lockstitch Sewing System with automatic thread trimmer (Vertical axis 2.0 fold-capacity hook / 12mm - pitch type)

High and long arm has been adopted.

The compound feed machine is suited to sew car seats, sofas, and bags. It is a walking foot machine provided with dramatically improved workability and functions which are required for sewing large products and extra heavy-weight materials.

The maximum stitch length is 12 mm

This model is the most-desired sewing machine for sewing furniture such as sofas. It is best suited to topstitching with a stitch length of a maximum 12mm - pitch. During the topstitching process, the long distance from the machine arm to the bed, in particular, effectively demonstrates the machine's improved workability.

| Model name | LU-2828V-7 | LU-2860V-7 | LU-2810V-7 |

|---|---|---|---|

| Type | 1-needle‚ Unison-feed‚ Lockstitch Sewing System (Shorter - thread remaining type) |

2-needle‚ Unison-feed‚ Lockstitch Sewing System |

1-needle‚ union-feed‚ lockstitch sewing system with automatic thread trimmer |

| Max. sewing speed | 3‚500sti/min | 3‚500sti/min | 3‚500sti/min |

| Max. stitch length | 9mm | 12mm | 9mm |

| Presser foot | 20mm | 20mm | |

| Alternating vertical movement (DL) |

9mm | 9mm | |

| Hook | Vertical axis 2.7 fold-capacity hook | Vertical axis 2.0 fold-capacity hook | |

| Needle | 134×35 Nm140(#22)‚ Nm125~180(#20~#24) |

134×35 Nm160(#23)‚ Nm125~200(#20~#25) |

135x35 Nm160 (#23) Nm125~Nm180 (#20~#24) |

| Thread | 60/3 ~ 20/3(#30~#5) | 60/3 ~ 10/3(#30~#0) | 60/3~20/3 (#30~#5) |