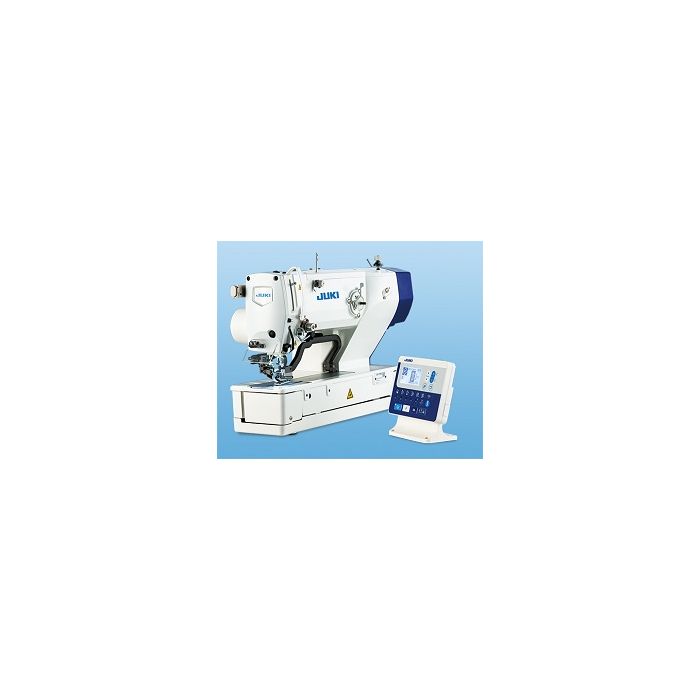

LBH-1790S

LBH-1790S

Computer-controlled, High-speed, Buttonholing Machine

JUKI Simple Series sewing machine LBH-1790S has been designed to have simplified and narrowed down capabilities that are essentially required to produce JUKI's established seam quality. In addition, it supports the operator with the voice guidance system to improve work efficiency.

JUKI's established quality is achieved with simplified functions

Voice guidance for the operator

This sewing machine is provided as standard with the voice-guidance system with

clock function.

The voice guidance can be used for the purpose of production support such as giving the operator information about the number of pieces produced, work progress management, and the operation rate of the sewing machine, though the initial setting is required.

The setting of functions such as the pattern number and the needle thread tension can be entered through the operation panel with ease. It is also possible to easily change the distance between buttonholes by means of the enlargement/reduction function.

The operation panel is provided as standard with a USB port. This means that the sewing machine data management and software updating can be carried out with ease by means of the USB port.

Higher productivity

This sewing machine achieves higher productivity with its improved capabilities such as the maximum sewing speed of 4,200 sti/min, quick acceleration at the beginning of sewing and quick deceleration at the end of sewing, increased thread trimming speed, and auto-lifter performance.

Main functions are driven electrically

The electric-driven mechanism has been adopted for the work clamp foot lifter, needle/bobbin thread trimmers, work clamp foot pressure regulator, cloth trimming knife, and thread tension controllers, thereby ensuring stable sewing that produces beautiful seams with less operating noise.

Work clamp foot lifting height

The work clamp foot lifting height can be set as desired. The work clamp foot can be lifted as high as 17 mm by the use of the reverse-rotation needle-up function.

Active tension (electronic thread tension control mechanism)

The needle thread tension can be separately set for the parallel section and bartacking section of the buttonhole seam according to various sewing conditions (thread, material, sewing speed, etc.) given, and those setting data can be stored in memory.

The needle thread tension can be changed over at the parallel and bartacking section of the buttonhole seam without fail, thereby producing a beautifully finished buttonhole stitch shape.

The needle thread tension to be employed at the beginning and end of sewing can be set individually. This helps prevent slip-off of the thread at the beginning of sewing and unravel of the finished seam.

Multiple-times knife dropping

Thanks to JUKI's unique multiple-times knife dropping function, the knife replacement is no longer required even when the buttonholing size is changed. In the case of small-lot production, frequent change in the sewing size and/or sewing of different cycle sewing patterns with different sewing sizes are required. In such a case, the number of times to drop the cloth trimming knife is automatically set according to the buttonholing size.

Easy changeover of sewing settings

Changeover between purl stitching and whip stitching and between single stitching and double stitching can be carried out with ease.

As many as 31 different buttonholing shapes are provided as standard

As many as 99 different sewing patterns can be stored in memory.

The sewing patterns that are stored in memory can be selected as desired through the operation panel.

**Please note that this product exclusive to Latin America.

| Model | LBH-1790SS |

|---|---|

| Sewing speed | 4‚200sti/min (at the time of delivery : 3‚600sti/min) |

| Size of cloth cutting knife | 6.4~31.8mm (1/4"~1-1/4") |

| Buttonhole length | Max. 41mm |

| Lift of the work clamp | 14mm (17mm when the reverse-rotation needle-up function is used) |

| Number of standard patterns | 31 patterns |

| Number of patterns that can be input | Max. 99 patterns |

| Machine head drive system | Compact AC servomotor (direct-drive system) |

| Needle (at the time of delivery) | DP×5(#11J)#11J~#14J |