LBH-1790AN Series

LBH-1790ANB (Shorter-thread remaining functions)

LBH-1790AN

LBH-1795AN (120mm presser type)

LBH-1796AN (220mm presser type)

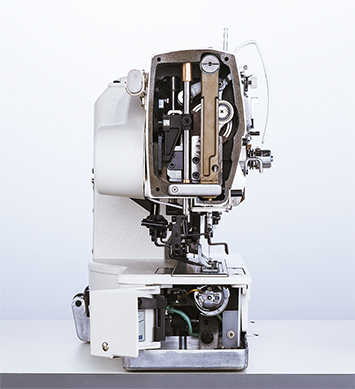

Shorter - thread remaining mechanism (LBH-1790ANB)

The length of the remaining bobbin thread becomes shorter, less than 2.5mm on average

The newly-developed shorter-thread remaining mechanism trims the thread short and eliminates the trouble of manual thread nipping.

Management of sewing performance and sewing machine by the utilization of IoT (Internet of Things)

Management, browsing, and editing of data can be carried out on the application software

Data on sewing machine adjustments made according to the product to be sewn can be transferred to a commercially available Android tablet in contactless mode. This enables quick check for uniform settings as well as confirmation of conditions of sewing machines in a sewing line, thereby facilitating setup changes. The operation panel is also provided as standard with a USB port. Data management and software updates can be carried out with ease using a USB thumb drive.

Data items of sewing can be numerically managed to ensure "stable quality" and "reduction in time required for setup changes".

Quantified sewing data can be externally taken from the sewing machine using an Android tablet or USB thumb drive.

*Android OS Version 6.0 is recommended to use JUKI Smart APP. (Operation is confirmed with respect to Versions 5.0 and later. ) Contact JUKI distributor in your area for how to use the application software.

Higher productivity

The maximum sewing speed is 4,200 sti/min., and the jump speed is 200 mm/s. The cycle time has been further reduced for continuous sewing.

Cycle sewing and continuous sewing

Cycle sewing

Twenty different programs can be registered, and as many as 30 different patterns can be stored in one program.

Continuous sewing

The machine is able to continuously sew two or more different patterns without requiring the work clamp foot to be lifted. As many as 20 programs can be registered, and six different patterns can be stored in one program. (Related parts need to be exchanged for optional ones.)

All drive mechanisms are electronically controlled

Electronic control of the material feed mechanism, needle feed mechanism, needle thread trimming mechanism, bobbin thread trimming mechanism, cloth trimming mechanism, presser lifter mechanism, and other mechanisms has been achieved.

All adjustment values are digitalized to enable the operator to set and store those values on the operation panel.

Operator-friendly environment

Operation with reduced noise is ensured by the adoption of the direct-drive motor.

The illuminance of the LED light is adjustable and is located on the underside of the arm jaw. It is provided as standard for all models of the LBH-1790AN Series.

The sewing product can further be placed on the machine easily by installing the auxiliary table (standard accessory). In addition, the needle entry is located in the center of the bed, promising easier positioning of the sewing product.

Many functions of the pedal

The machine is provided as standard with a newly-developed auto-lifter driven by a stepping motor. This helps reduce the operator's fatigue. As for the pedal, one-pedal and two-pedal models can both be changed over and the intermediate stop, which facilitates positioning of the sewing product, can be specified.

The work clamp foot lift can be set as desired. The reverse-rotation needle-up function offers a maximum work clamp foot lift of 17mm.]

* Please order a two-pedal model by a part.

JUKI's unique active tension (Electronic thread tension control system)

Needle thread tension for sewing parallel and bartacking sections of buttonholes can be separately controlled through the operation panel and stored in memory according to various sewing conditions (e.g., type of thread, type of material, and sewing speed).

The machine is able to change the needle thread tensions at the parallel and bartacking sections of the buttonhole, to produce a beautiful buttonhole shape. This capability helps greatly in preventing thread breakage.

Needle thread tension is activated at the beginning and end of sewing. This prevents unthreading of the needle thread and thread fraying that is likely to occur at the beginning of sewing.

Thread tension for basting stitching can be specified separately.

Basting stitch mechanism is effective for the production of beautiful buttonholes

The basting stitch is effective on elastic materials such as knits. Basting stitch: Since the needle thread is tucked in without fail, it will never jut out of the buttonhole seams. Basting stitches can be sewn by nine rounds.

The machine is equipped with multiple knife-dropping functions

Thanks to the multiple knife-dropping functions, it is no longer required that the knife be changed at the time the buttonhole size is changed. The number of knife dropping times can be automatically set according to the buttonholing size in cases where the buttonhole size is frequently changed for small-lot productions or during the cycle sewing of buttonholes that are different in size.

The double-acting stepping motor type knife mechanism is free from the faulty dropping/returning of the knife.

The knife supports sewing lengths of 41mm at the maximum. In addition, knife mechanisms for 70mm and 120mm are optionally available.

Sewing settings can be easily changed

For a changeover between purl stitch and whip stitch, threading of bobbin, as well as the bobbin thread tension needs to be changed.

For double stitching, the bartacking section is skipped and only the parallel sections are sewn twice. This prevents any excessively tight finished in the bartacking section of the buttonholes.

The first and second round stitched can be sewn using different widths.

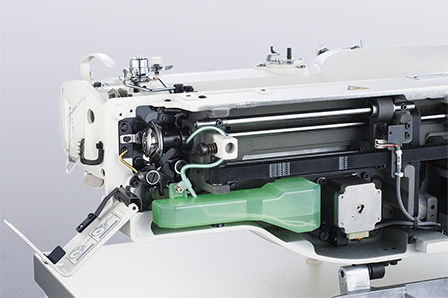

The machine eliminates oil stains on the sewing product

Thanks to our advanced dry-head technology, no lubrication is required except for the hook section. This eliminates oil stains on the sewing product. The machine can be completely changed into a dry-head machine by replacing the hook with an optional non-lubricated hook. (In this case, the maximum sewing speed will be 3,300sti/min)

Adjustment of the hook oil quantity

The newly installed "hook oil quality adjustment screw" can be found by opening the hook lid cover. With this screw, the operator is able to adjust the oil quantity in the hook with ease.

Oil can be easily added to the hook oil quantity tank with an oiler.

The machine is provided as standard with as many as 31 stitch patterns for buttonholing

It is able to store 99 different patterns in its memory, which can be selected as desired from the operation panel.

| Model | LBH-1790ANB | LBH-1790AN | LBH-1795AN | LBH-1796AN |

|---|---|---|---|---|

| Sewing speed | Max. 4‚200sti/min‚ Normal 3‚600sti/min When the non-lubricated hook (optional) is used: 3‚300sti/min | |||

| Needle bar stroke | 34.6mm | |||

| Size of cloth cutting knife | 6.4~22.2mm (1/4"~7/8") | 6.4~31.8mm (1/4"~1-1/4") | 6.4~25.4mm | |

| Bartacking width | Max. 4.0mm | Max. 5.0mm (with special-specification part: Max. 10mm*) | Max. 5.0mm | |

| Buttonhole length | Max. 25mm | Max. 41mm (optional: 70mm‚ 120mm) |

Max. 120mm | Max. 220mm |

| Precision of needle throwing mechanism | 0.05mm | |||

| Needle thread tension | Active tension (electronic thread tension control system) | |||

| Number of stitches | Automatically computed from the size of the buttonhole and stitch pitch | |||

| Needle (at the time of delivery) | DP×5 (#11J) #11J~#14J | |||

| Hook | DP type‚ full-rotary hook Non-lubricated hook (optional) | |||

| Lift of the work clamp | 14mm (17mm when the reverse-rotation needle-up function is used) | Parallel lifting 6mm | ||

| Auto-lifter | Provided as standard (stepping motor type) | |||

| Needle throwing system | Stepping motor | |||

| Cloth feeding system | Intermittent feed by stepping motor | |||

| Cloth cutting knife system | Stepping motor | |||

| Number of standard patterns | 31 patterns | |||

| Number of patterns that can be input | Max. 99 patterns | |||

| Bobbin thread winder | Built-in the machine head | |||

| Machine head drive system | Compact AC servomotor (direct-drive system) | |||

| Power requirement / Power consumption | 3-phase 200~240V/250VA | |||

| Lubrication | Only the hook section needs a minute-quantity lubrication. No lubrication is required when the non-lubricated hook (optional) is used. |

|||

| Lubricating oil | Hook: JUKI New Defrix Oil No.1 (equivalent to ISO VG7) | |||

| Weight | Machine head (include motor) 55kg‚ Control box 5.5kg |

Machine head (include motor) 55kg‚ Control box 6kg |

||