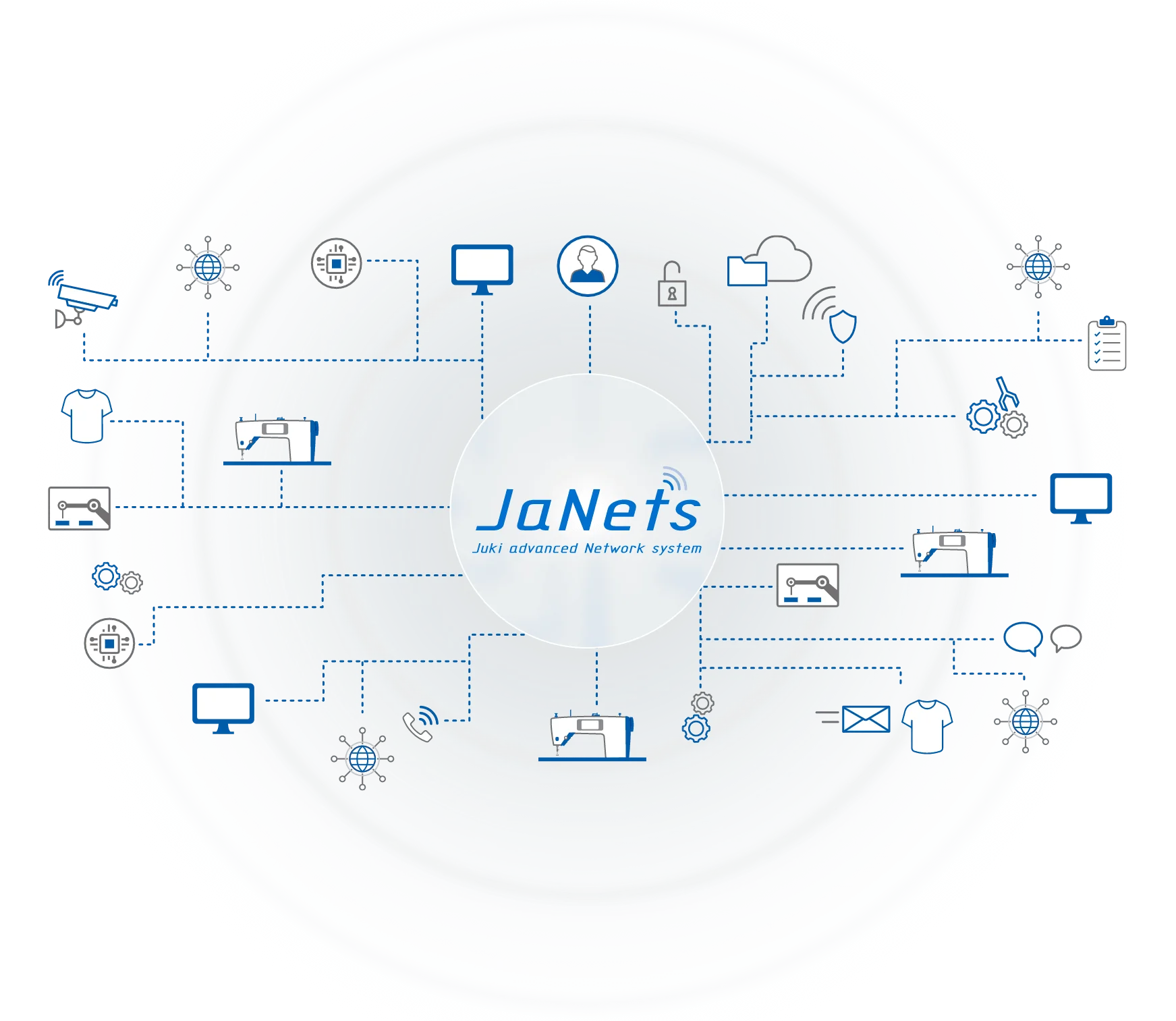

JaNets

YOUR COMPREHENSIVE SHOP FLOOR CONTROL SYSTEM

Revolutionize your production process with real-time tracking and monitoring. Increase efficiency, reduce costs, and outpace competition with JaNets.

JaNets, Juki Advanced Network System, is a revolutionary shop floor control system that optimizes your production process through real-time tracking and monitoring. Developed by CSG in cooperation with JUKI, and based on the BlueCherry Shopfloor Control System, JaNets utilizes cutting-edge technology to interlink sewing machines on the shop floor, providing a wealth of data on all aspects of production.

Unleash Maximum Efficiency with JaNets

JaNets is designed for businesses in the manufacturing sector, particularly those in the apparel industry that use sewing production lines. It is an invaluable tool for factories of all sizes, from large operations with numerous operators to smaller factories striving to gain as much advantage as possible from an efficient production process. Whether you are a line manager, an engineer, or part of the management team, JaNets gives you the tools and data you need to optimize your production line and outpace the competition.

Optimized Productivity

JaNets offers unrivaled real-time tracking and monitoring of production processes, helping identify and rectify bottlenecks, underperforming operators, and problematic machines.

Improved Communication

With terminals at each workstation, JaNets enhances communication across the factory floor, reducing the reaction time to problems and streamlining administrative tasks.

Streamlined Administration

JaNets reduces time spent on menial administrative work, allowing line managers to focus on the shop floor and more critical tasks.

Integration with Juki’s Digital Sewing Machines

JaNets, in combination with Juki’s digital sewing machines, provides detailed analytics, faster updates, and more accurate data for better decision-making and performance optimization.

Reduced Cycle Times

JaNets’ real-time monitoring and data-based decision making significantly reduce production cycle times.

Lower Labor Costs

By streamlining administrative tasks and improving operator efficiency, JaNets reduces both direct and indirect labor costs.

Decreased Working Hours

JaNets’ efficiency improvements mean you can achieve the same output with fewer working hours.

Increased Quality

Detailed data from Juki’s digital sewing machines and real-time monitoring help improve quality control, reducing errors and enhancing final product quality.

Boosted Productivity

Through efficiency gains, improved communication, and streamlined administration, JaNets boosts overall productivity in your factory.

Benefits

ROI

JaNets delivers a rapid return on investment, with medium-sized factories typically seeing a return in just 12-24 months.

Improved Output

JaNets enhances overall productivity, leading to increased output without a proportional increase in cost.

Reduced Wasted Time

By eliminating unproductive time and streamlining operations, JaNets significantly reduces wasted hours on the shop floor.

Lower Costs

Through efficiency gains and waste reduction, JaNets helps to lower overall production costs, further contributing to a speedy ROI.

JANETS: TAILORED SOLUTIONS FOR EVERY PRODUCTION NEED

JaNets PRO

Includes all of these great features:

- JUKI Smart Machine data collection

- Off standard reporting

- Web application Dashboards

- Production & WIP Reporting

- View videos/PDF on terminals

- Operator & Style Management

- Two-way communication

JaNets PRO ESSENTIAL

Includes all the features of the JaNets PRO package, and:

- Big screen display KPI dashboards

- Two Way ERP Interface or API

- Advanced Production Tracking

- Enhanced WIP reporting & Analysis

- Operator Time & Attendance Management

- Quality Control Module

JaNets PRO ENTERPRISE

Includes all the features of both the JaNets PRO and JaNets PRO ESSENTIAL packages, and:

- Flexible incentives

- Training curves

- Line balancing

- Cost analysis

- Sub/Add rules

- Bundle overrides

- Payroll interface