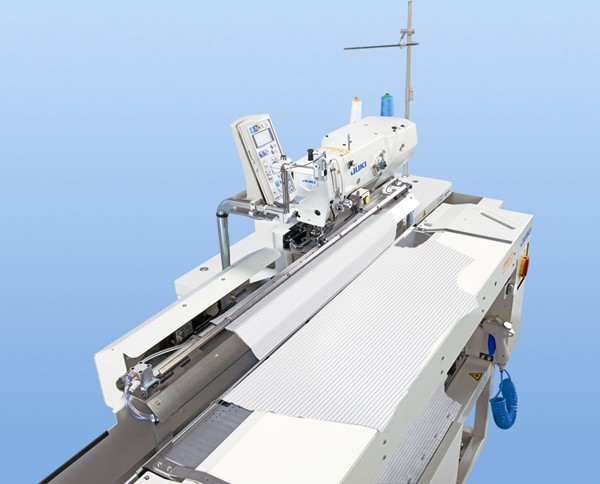

AC-172N-1790

High-speed, Computer-controlled Buttonholing Indexer

The preset mechanism helps increase productivity!

What is the preset mechanism?

It is the facility that allows placement of the material to be sewn next on the preset board while the sewing machine is engaged in the sewing of the current material.

Since the automatic buttonholing indexer carries out buttonholing successively, the operator conventionally has had waiting time while the sewing machine is in operation (for buttonholing). JUKI's preset mechanism allows the operator to place the subsequent garment body to be sewn on the preset board while the sewing machine is still engaged in the sewing of the current garment body (so-called overlapping work). Consequently, the operator now can use his/her waiting time effectively during operation to achieve increased productivity.

Sub-clamp device which enhances the applicability of the sewing machine to vertical-strip patterns

The sewing machine comes with a newly-developed mechanism that prevents slippage of the material at the time of its delivery from the preset board to the sewing machine. This helps increase the applicability of the sewing machine to buttonhole vertical-striped garments.

The independent sub-clamp mechanism of the carriage unit on the sewing machine head securely clamps the material upon delivery of the material from the preset board to the sewing machine, thereby preventing the material from slipping out of position. As a result, the sewing machine is allowed to achieve accurate buttonholing of top-center plaits with consistency.

High-performance indexer mechanism

A stepping motor controls material feed amounts in increments of 0.1 mm to feed materials with both consistency and accuracy. The machine is able to sew 1 to 20 buttonholes and store 20 different stitching patterns in its memory.

The sewing machine is provided as standard with a facility that moves the carriage unit synchronously with the operation of the sewing machine during sewing, thereby enabling accurate and unfailing feed of the material while preventing material slack.

The sewing machine comes with the LBH-1790 head, which is highly evaluated in terms of functions and performance

The AC-172N-1790 is equipped with the highly-evaluated LBH-1790 as its machine head. The needle thread tension is changed over without fail at bank parts and bartacking parts of a buttonhole by means of the highest sewing speed of 4,200 sti/min and the unique active tension (electronic thread tension control mechanism), thereby achieving beautiful-shaped buttonholes.

In addition, fastening stitches prevent the seams from unraveling at the end of sewing. It is also possible to program other stitching styles such as double buttonholing.

Indexer operation panel

The adjusting keys which are frequently operated by the operator for adjusting buttonholing are arranged in a similar configuration to the standard panel for the LBH-1790. The operator is therefore able to directly adjust the buttonholing to achieve improved operability.

Oil stains on the sewing product are eliminated

Thanks to our advanced dry-head technology, no lubrication is required to expect for the hook section. This eliminates oil stains on the sewing product. Only a minute quantity of clean oil is fed to the hook section from the oil tank. The machine can be completely changed into a dry-head machine by replacing the hook with an optional non-lubricated hook.

Stacker

It is a device for automatically stacking garment bodies after having been buttonholed. (Space-saving type stacker built inside the main body)

The stacker, which clamps even narrow garment bodies without fail, increases the efficiency of the material taking/stacking operation, thereby helping further increase productivity.

Knee Switch

This switch is operated with the knee to actuate the sewing machine (sub-clamp device).

The knee switch can be turned on by the operator with his/her knee while he/she still holds a garment body on the sewing machine with both hands. As a result, the operator is able to place the material securely on the sewing machine to reduce the time required for accurate positioning of the material. Needless to say, a hand switch is also provided.

In addition, if the operator turns on the switch after having placed the material on the sewing machine, the sub-clamp device will automatically bring the subsequent material to the sewing position after the completion of buttonholing of the current material to allow the sewing machine to immediately start the next buttonholing. This function works effectively, especially in cases where the operator is operating two or more sewing machines or is carrying out other work simultaneously.

| Model | AC-172N-1790 |

|---|---|

| Machine head | LBH-1790 (exclusive machine head for AC) |

| Max. sewing speed | 4‚200sti/min |

| Stitch length | Max. 25mm |

| Cloth trimming length | 6.4~19.1mm (1/4"~3/4" inch) |

| Feed direction | Right (for men's garments) or left (for ladies' garments) |

| Number of patterns that can be input | 20 patterns |

| Number of buttonholes | 1~20 pcs. |

| Needle | DP×5 #11J~#14J (Needle installed at the time of delivery #11J) |